Gasoline Engine with Manual Transmission Training Equipment

The Gasoline Engine with Manual Transmission Training Equipment comprises an electronically controlled engine paired with a manual transmission. This system facilitates hands-on training exercises such as engine starting, acceleration/deceleration control, and manual gearshift operations.

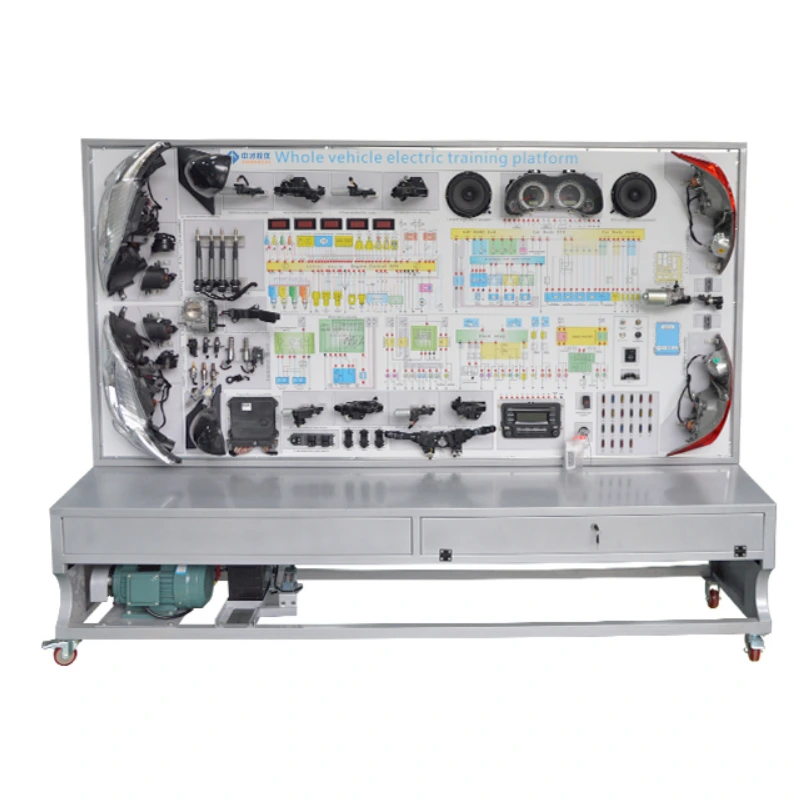

Our product in action

Product Introduction

| Name | Gasoline Engine with Manual Transmission Training Equipment |

| Category | Automotive education trainer |

| Brand | Zhongcai |

| Place of Origin | China Guangzhou |

| Certification | CE, ISO |

| Parameter | Customized |

| Power supply | Three-phase four-wire(Three-phase five-wire 380V±10% 50Hz) |

| Input supply | AC 220V±10% 50Hz |

| Working power | DC 12V |

| Size(L*W*H) | 1700mm*1000mm*1700mm |

Product Overview

The Gasoline Engine with Manual Transmission Training Equipment consists of an electronically controlled engine and a manual transmission. It enables practical operations including engine starting, acceleration, and deceleration, as well as gear shifting experiments with the manual transmission. The equipment accurately demonstrates the structural components and working principles of both the electronically controlled gasoline engine and manual transmission.

This Automotive Training Equipment is ideal for teaching applications in secondary and higher vocational-technical schools, general education colleges, and training institutions. It supports both theoretical instruction and practical maintenance training for automobile engines and dual-clutch automatic transmissions.

Core Features

1. Fully Functional Engine and Transmission System

The Gasoline Engine with Manual Transmission Training Equipment features an operational, electronically controlled gasoline engine and manual transmission. It comprehensively demonstrates both the electronic control system’s and manual gearbox’s structure and working principles, making it ideal for in-depth instruction and hands-on practice in automotive engine and transmission technology.

2. Durable and Educational Panel Design

The control panel consists of a 4mm thick, high-grade aluminum composite board that is corrosion-resistant, impact-resistant, pollution-resistant, fire-resistant, and moisture-resistant. Its surface undergoes a special primer spraying treatment and features a colorful, fade-resistant circuit diagram. This enables students to visually compare the schematic with actual engine and transmission components, facilitating an intuitive understanding of the control system’s working principles.

3. Real-Time Display of Key Parameters

The automotive training equipment features installed instrument clusters, a fuel pressure gauge, and a vacuum pressure gauge. These instruments provide real-time monitoring of engine speed, vehicle speed, manual transmission gear position, fuel injection pressure, and intake manifold pressure, enabling dynamic observation and data analysis during operation.

4. Comprehensive Signal Testing Capabilities

The training equipment features diagnostic terminals that enable users to directly measure electrical signals – including resistance, voltage, current, and frequency – from sensors, actuators, and ECU pins on the panel. This configuration facilitates hands-on learning of fault diagnosis and electronic control system analysis.

5. Advanced Diagnostic and Safety Features

The system incorporates an integrated diagnostic connector compatible with both OEM and aftermarket automotive scanners. It enables key functions including ECU code reading, fault code retrieval and clearing, data stream analysis, component testing, parameter configuration, and waveform diagnostics. The training bench additionally features a throttle control device, braking system, protective covers, a utility steel work surface, and a welded steel base equipped with self-locking casters and safety handrails – ensuring both full functionality and operational safety.

Technical Specifications

Product Name: Gasoline Engine with Manual Transmission Training Platform

Model: ZC-QCA02

Working Power Supply: DC 12V

Fuel Grade: according to engine model

Fuel Tank Capacity: 10L

Working Temperature: -40℃~+50℃

Steel Pipe: 40*60*3mm

Panel Cabinet: 1.5mm cold plate stamping.

Moving Casters: 120*80mm

Appearance: 1700*1000*1700mm

Get in touch

We’re here to assist you with any questions, inquiries, or support needs you may have. Whether you’re interested in our products, need technical assistance, or want to discuss a custom solution, our team is ready to help.