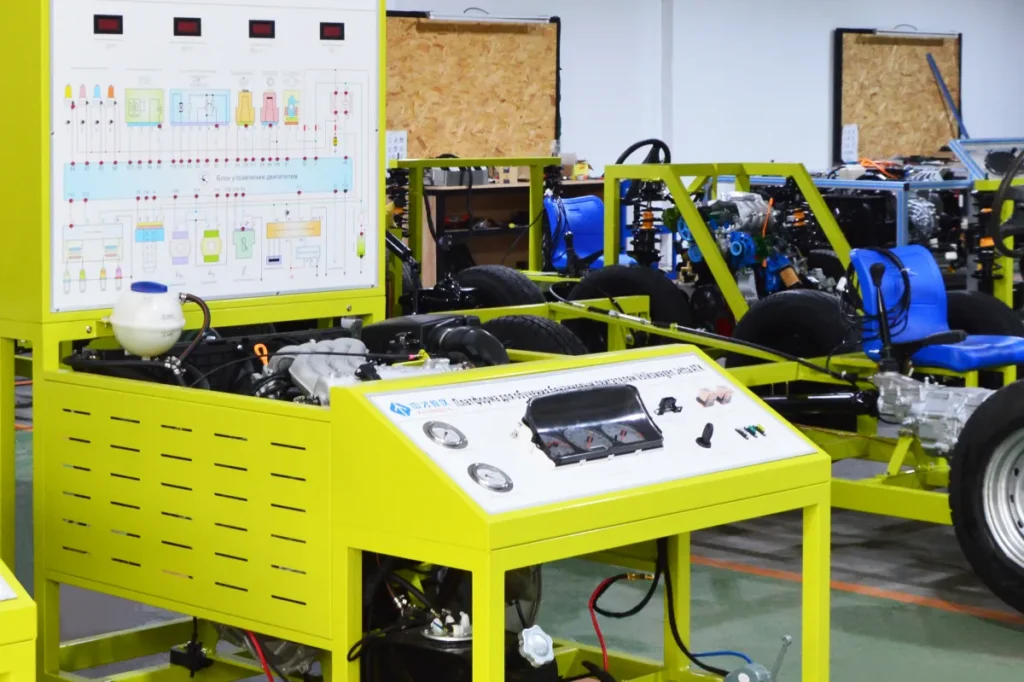

Automotive ABS Brake System Training Equipment

The automotive ABS brake system training equipment accurately replicates a real vehicle ABS braking system, complete with a working principle diagram that visually illustrates the ABS operational process during emergency braking conditions.

Product Introduction

| Name | Automotive ABS Brake System Training Equipment |

| Category | Automotive Education Equipment |

| Brand | ZhongCai |

| Place of Origin | China Guangzhou |

| Certification | CE, ISO |

| Parameter | Customized |

| Power supply | Three-phase four-wire(Three-phase five-wire 380V±10% 50Hz) |

| Input supply | AC 220V±10% 50Hz |

| Working power | DC 12V |

| Size(L*W*H) | 1500mm*1000mm*1700mm |

Product Overview

The automotive ABS brake system training equipment replicates an actual vehicle ABS braking system, featuring a working principle diagram that visually demonstrates the ABS operation process during emergency braking. This system fulfills all teaching requirements for ABS brake system structure and operation demonstration. It is ideally suited for theoretical instruction as well as diagnostic and maintenance training of automotive ABS brake systems.

Core Features

1. Real Car-Based ABS Brake System Structure

The automotive ABS brake system training equipment replicates an actual vehicle ABS braking system, accurately demonstrating its complete composition and structural configuration. This authentic representation enables trainees to develop a thorough understanding of ABS components and their spatial arrangement within a vehicle.

2. Dynamic ABS Operation Simulation

An asynchronous motor drives both front and rear axles to simulate actual vehicle movement. When suddenly applying the brake pedal, the ABS system engages. The brake discs maintain slight rotation while the pedal exhibits repeated pulsation, accurately demonstrating authentic ABS operation during emergency braking scenarios.

3. Intuitive Circuit and Hydraulic Diagram Display

The automotive ABS brake system training equipment features a full-color UV-printed circuit diagram and hydraulic pipeline layout. This visual reference allows trainees to directly compare schematics with the physical ABS brake system, enhancing their understanding and analysis of the system’s control principles.

4. Comprehensive Electrical Signal Detection

Equipped with multiple diagnostic terminals, the automotive training equipment allows direct measurement of electrical signals from each sensor and control unit. Trainees can test for resistance, voltage, current, and frequency signals, supporting in-depth analysis and hands-on learning of ABS system diagnostics.

5. Real-Time Hydraulic Pressure Monitoring

The automotive ABS brake system training equipment incorporates a set of pressure gauges for real-time monitoring of hydraulic pressure variations in both the master cylinder and all four wheel cylinders. This enables users to observe hydraulic system dynamics during ABS operation.

6. Fault Diagnosis and Analysis Interface

The automotive training equipment integrates a fault indicator light and OBD-II diagnostic port, compatible with both manufacturer-specific and universal diagnostic tools. This system enables comprehensive ABS/EBD electronic control system diagnostics, including: ECU code retrieval, DTC reading/clearing, live data stream analysis, actuator testing, parameter configuration, and waveform analysis.

Technical Specifications

Product Name: Automotive ABS brake system training platform

Model: ZC-QCB30

Dimensions: 1500 × 1000 × 1700 mm

Power Supply: DC 12V

External Power Supply: AC 220V±10% 50Hz

Working Temperature: -40℃-+50℃

Brake Cylinder Pressure Gauge: 0-100kg/psi

Asynchronous Motor:

Voltage: AC 220V 50Hz

Current: 11.8A/6.8A

Power: 3KW

Speed: 1420r/min