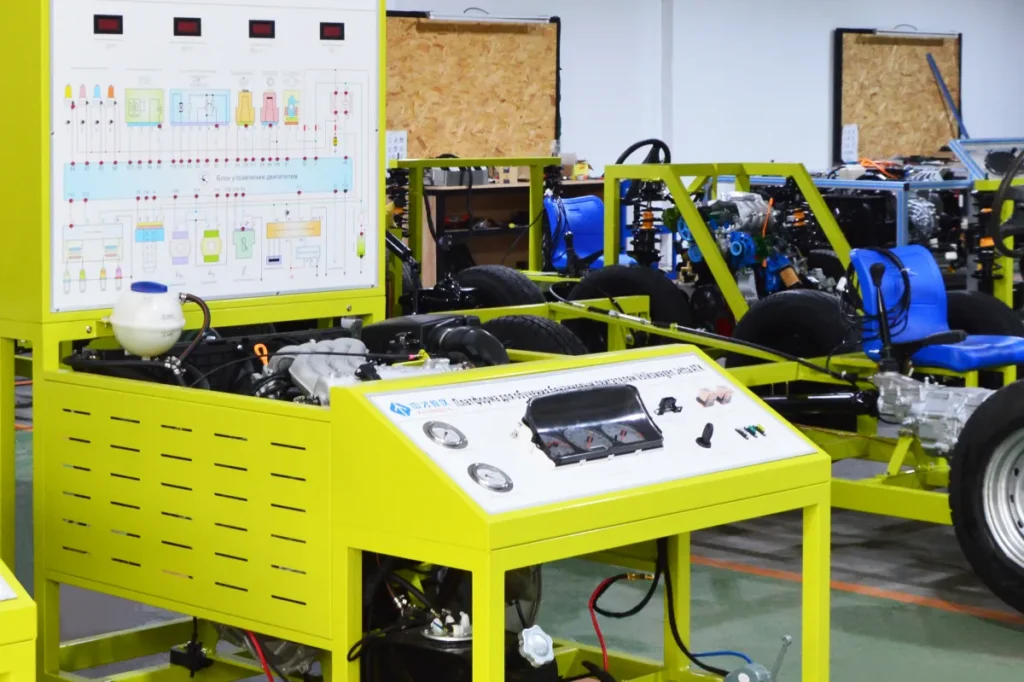

Automotive Hybrid Engine Training Equipment

The Automotive Hybrid Engine Training Equipment is based on an actual vehicle’s hybrid engine and electronic transmission system. It enables practical operations including engine starting, acceleration, and deceleration, along with operation of the electronic transmission, while clearly demonstrating the hybrid engine’s composition, structure, and working principles.

Product Introduction

| Name | Automotive Hybrid Engine Training Equipment |

| Category | Education Equipment |

| Brand | Zhongcai |

| Place of Origin | China Guangzhou |

| Certification | CE, ISO |

| Parameter | Customized |

| Power supply | Three-phase four-wire(Three-phase five-wire 380V±10% 50Hz) |

| Input supply | AC 220V±10% 50Hz |

| Working power | DC 12V |

| Size(L*W*H) | 1740mm*1400mm*1700mm |

Product Overview

The Automotive Hybrid Engine Training Equipment is based on the original vehicle’s hybrid engine and electronic transmission bridge. It allows for practical operations such as starting, accelerating, and decelerating the engine and electronic transmission bridge, while accurately demonstrating the composition, structure, and working process of the hybrid engine.

This automotive training equipment is suitable for teaching and maintenance training in secondary and higher vocational-technical colleges, general education institutions, and training centers.

Core Features

1. Realistic Hybrid Engine Simulation

This Automotive Hybrid Engine Training Equipment features a fully functional hybrid petrol-electric engine, accurately replicating the structure and operating principles of a hybrid power system. It enables learners to gain hands-on experience, allowing them to observe and understand the system’s complete composition and real-time operation, effectively bridging the gap between theory and practice.

2. Durable and Educational Control Panel

The automotive training equipment is constructed from a 4mm-thick, high-quality aluminum-plastic composite panel, offering resistance to corrosion, impact, stains, fire, and moisture. Its surface undergoes a special primer-coating treatment, ensuring long-term durability. A fade-resistant, full-color wiring diagram is printed on the panel, enabling trainees to easily cross-reference the schematic with the actual engine system and analyze the control system’s working logic.

3. Integrated Display and Diagnostic Features

The training equipment comes equipped with automotive instrument clusters and a multifunctional display, capable of displaying dynamic data such as power transfer processes, vehicle speed, and system parameter changes. It includes electronic control system fault indicator lights to facilitate troubleshooting. Diagnostic connectors enable integration with standard automotive scan tools for reading/clearing fault codes and accessing real-time data streams from systems including the engine, hybrid control unit, and power supply.

4. Comprehensive Testing and Safety Configuration

The Automotive Hybrid Engine Training Equipment features accessible test terminals for directly measuring signals from sensors, actuators, the engine control unit, transmission, and hybrid components, including resistance, voltage, current, and frequency. Additional features include a throttle control unit for acceleration testing, protective covers for the radiator and flywheel, a master power switch, and a 20 cm-wide front steel platform for manuals or instruments. The steel-welded base is treated with a durable spray coating and mounted on lockable casters to ensure safe, mobile, and reliable operation.

Technical Specifications

Product Name: Automotive hybrid engine trainer

Model: ZC-QCG54

Input Power: three-phase five-wire 380V±10% 50Hz

Dimensions: 1740×1400×1700mm (length×width×height)

Power Supply: DC 12V

Fuel Grade: according to engine model

Fuel Tank Capacity: 10L

Working Temperature: -40℃~+50℃

Steel Pipe: 60*40*3mm

Panel Cabinet: 1.5mm cold plate stamping;

Moving Casters: 120*80mm