Automotive Automatic Air Conditioning Training Equipment

Product Introduction

| Name | Automotive Automatic Air Conditioning Training Equipment |

| Category | Automotive education trainer |

| Brand | Zhongcai |

| Place of Origin | China Guangzhou |

| Certification | CE, ISO |

| Parameter | Customized |

| Power supply | Three-phase four-wire (Three-phase five-wire 380V±10% 50Hz) |

| Input supply | AC 220V±10% 50Hz |

| Working power | DC 12V |

| Size(L*W*H) | 1500mm*1000mm*1700mm |

Product Overview

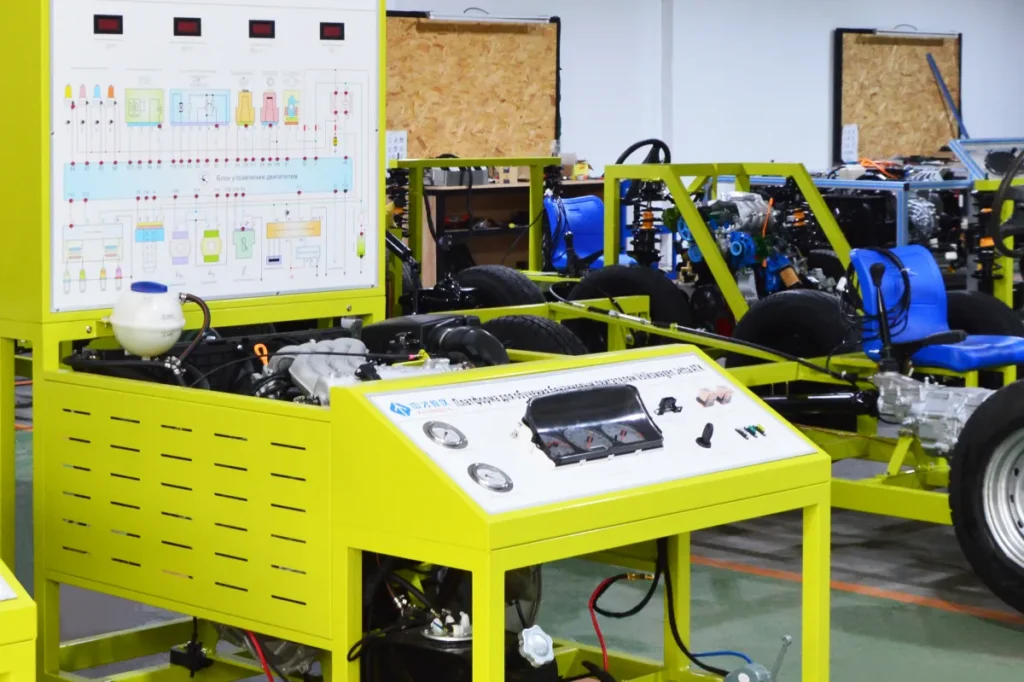

The Automotive Automatic Air Conditioning Training Equipment is designed based on an actual automotive automatic air conditioning system. It fully demonstrates the system’s composition and working process.

It is suitable for meeting the teaching needs of secondary and higher vocational colleges, technical institutes, general education colleges, and training institutions in the theory and maintenance training of automotive automatic air conditioning systems.

Core Features

1. Fully Functional Automotive Automatic Air Conditioning System

This Automotive Automatic Air Conditioning Training Equipment features a fully operational, real automotive automatic air conditioning system, comprehensively demonstrating its structural components and working process. It enables students to clearly understand the functionality of automatic climate control in modern vehicles.

2. Interactive Control with Realistic Operation

The Automotive Training Equipment is powered by an electric motor that drives the air conditioning compressor. By operating the air conditioning control panel, users can realistically simulate and observe the working principles and actual operation of an automotive automatic climate control system, enhancing both theoretical knowledge and practical skills.

3. Durable Panel Design with Integrated Circuit Diagrams

The training equipment is constructed from 4mm-thick, high-grade aluminum-plastic composite panels that resist corrosion, impact, dirt, fire, and moisture. The surface is coated with a specially treated primer and features full-color, fade-resistant circuit and working principle diagrams printed using UV flatbed technology. This design enables students to visually match actual components with schematic diagrams for more effective system analysis.

4. Built-in Measurement and Diagnostic Terminals

This Automotive Automatic Air Conditioning Training Equipment features test terminals on its panel, enabling direct measurement of electrical signals in the A/C system—including resistance, voltage, current, and frequency. These diagnostic capabilities facilitate hands-on learning in fault detection and system behavior analysis.

5. Complete Practical Training Equipment

The Automotive Training Equipment features real-time pressure and temperature gauges that display changes in A/C line pressure and inlet/outlet air temperatures. It also includes refrigerant charging and leak detection practice equipment. The steel base incorporates a 20 cm metal desktop at the front for placing documents or instruments, while rounded safety handrails and self-locking casters ensure mobility, durability, and operational safety.

Technical Specifications

Product Name: Whole Vehicle Electric Training Platform

Model: ZC-QCD28

External Dimensions: 1500×1000×1700mm (L×W×H)

External Power Supply: AC 220V ±10%, 50Hz

Operating Voltage: DC 12V

Refrigerant: R134a

Operating Temperature: -40°C to +50°C

Asynchronous Motor:

Voltage: AC 220V

Power: 2.2 kW

Speed: 1420 rpm

Steel Pipe: 60 × 40 × 3 mm

Panel Cabinet: 1.5 mm cold-rolled steel plate stamped and formed;

Mobile Casters: 120 × 80 mm