Automotive Automatic Transmission Training Equipment

The Automotive Automatic Transmission Training Equipment is powered by a variable-speed asynchronous motor, enabling the transmission system to simulate real operating conditions such as gear shifting, neutral starts, and forward/reverse rotation. The inverter includes an electronic thermal relay for setting the motor’s rated current to prevent overload, while integrated acceleration and deceleration functions minimize mechanical stress during start-stop operations.

Product Introduction

| Name | Automotive Automatic Transmission Training Equipment |

| Category | Education Equipment |

| Brand | Zhongcai |

| Place of Origin | China Guangzhou |

| Certification | CE, ISO |

| Parameter | Customized |

| Power supply | Three-phase four-wire(Three-phase five-wire 380V±10% 50Hz) |

| Input supply | AC 220V±10% 50Hz |

| Working power | DC 12V |

| Size(L*W*H) | 1600mm*900mm*1700mm |

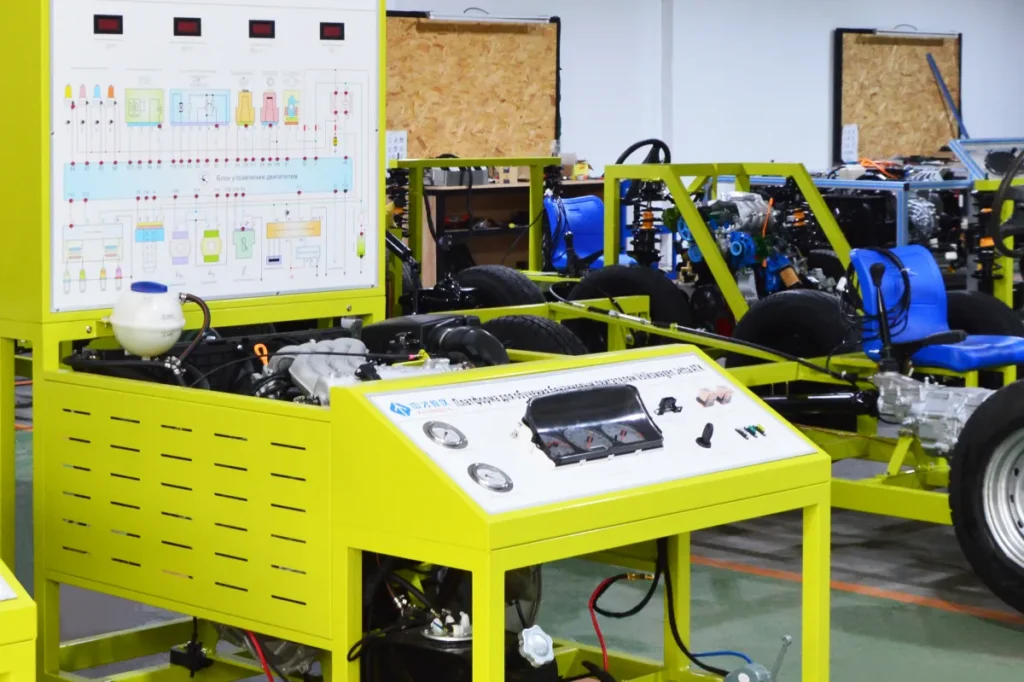

Product Overview

The Automotive Automatic Transmission Training Equipment is based on an actual automatic transmission assembly, with an adjustable-speed asynchronous motor serving as the power source. It simulates real-world operations, including gear display, neutral start, and forward/reverse gear shifting, while accurately demonstrating the structure and working process of an electronically controlled automatic transmission. This makes it ideal for theoretical instruction and maintenance training in various educational settings.

Core Features

1. Educational Focus and Realistic Simulation

This Automotive Automatic Transmission Training Equipment serves as an essential educational tool for understanding modern transmission systems. Students gain hands-on experience with fully operational electronic automatic transmissions, including torque converters, planetary gear sets, clutches, and hydraulic systems. The equipment allows observation of key phenomena like torque converter operation and clutch slip, providing comprehensive training for automotive, heavy-duty, and electric vehicle applications.

2. Comprehensive Safety and Structural Design

The automotive training equipment incorporates safety features including motor protection covers and output shaft guards to ensure safe operation during practical training. Its cabinet panel consists of 1.5mm cold-rolled steel with a rear maintenance door, while the base features welded steel construction with a spray-coated surface and lockable caster wheels for enhanced mobility, durability, and safety.

3. High-Quality Display and Circuit Illustration

The training equipment is constructed from high-grade aluminum composite board, offering resistance to impact, pollution, fire, and moisture. It includes UV-treated flat-panel printed full-color circuit diagrams that resist fading. Students can visually match the circuit diagrams with actual components, simplifying the understanding and analysis of automatic transmission system control principles.

4. Real-Time Parameter Monitoring and Diagnostics

The Automotive Automatic Transmission Training Equipment features integrated automotive instruments that display real-time data including engine speed, vehicle speed, and transmission gear positions. The system includes a diagnostic port compatible with standard OEM automotive scanners, enabling students to read and clear fault codes while performing self-diagnostics on both engine and automatic transmission control systems.

Technical Specifications

Product Name: Automotive automatic transmission anatomy trainer

Model: ZC-QCB39

Dimensions: 1600×900×1700mm (length×width×height)

Input Power: AC 220V±10% 50Hz

Working Power: DC 12V

Asynchronous Motor:

Current: 8.2A/4.7A

Power: 4KW/5.5kw

Speed: 2880r/min

Inverter:

Power: 5.5KW/7.5KW

Output: 9A/13A 0~400Hz

Working Temperature: -40℃~+50℃

Steel Pipe: 60*40*3mm

Moving Casters: 100*50mm

Panel Cabinet: 1.5mm cold plate stamping, maintenance door on the back