Hybrid Transmission and Engine Automotive Training Equipment

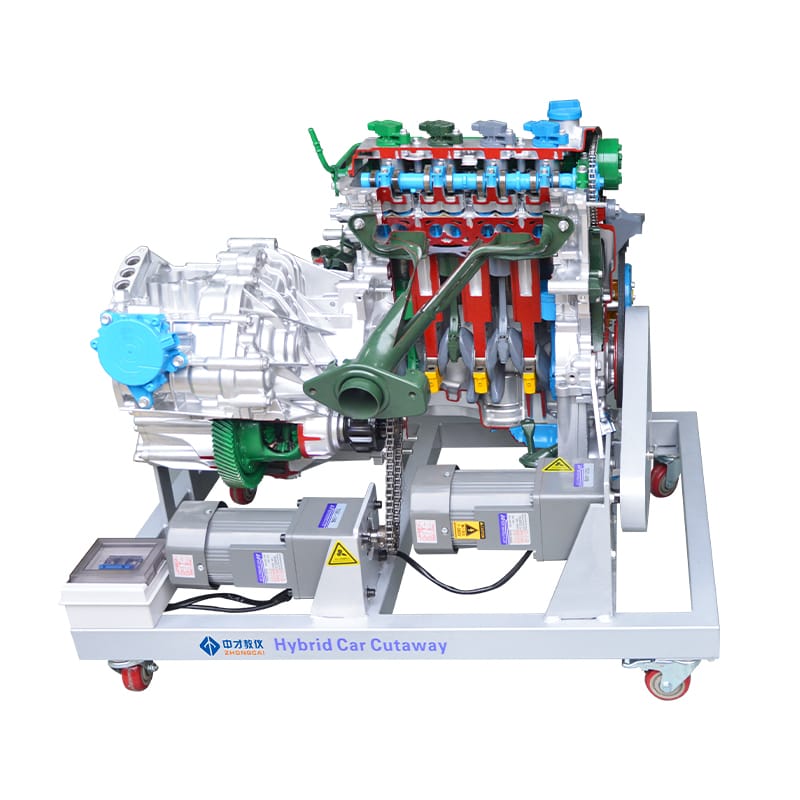

The Hybrid Transmission and Engine Automotive Training Equipment utilizes a refurbished hybrid power system assembly, including key components such as the engine, generator, and motor. Each part is cross-sectioned with precision to reveal the internal and external structures. The layout is designed for optimal visibility, enabling trainees to clearly observe the structural composition and mechanical design of hybrid vehicle powertrains.

Product Introduction

| Name | Hybrid Transmission and Engine Automotive Training Equipment |

| Category | Education Equipment |

| Brand | Zhongcai |

| Place of Origin | China Guangzhou |

| Certification | CE, ISO |

| Parameter | Customized |

| Power supply | Three-phase four-wire(Three-phase five-wire 380V±10% 50Hz) |

| Input supply | AC 220V±10% 50Hz |

| Working power | DC 12V |

| Size(L*W*H) | 1400mm*800mm*1000mm |

Product Overview

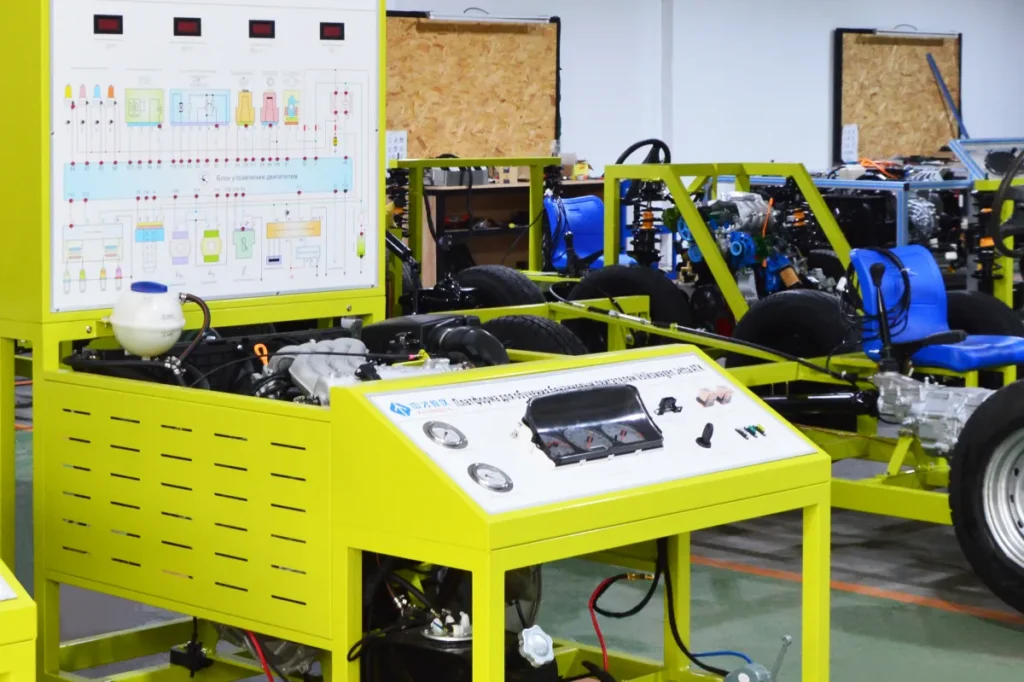

This Hybrid Transmission and Engine Automotive Training Equipment is specifically designed for educational institutions focusing on hybrid vehicle technology. It offers an effective tool for teaching the principles of hybrid power systems and mechanical transmission mechanisms. By bridging theoretical knowledge with visual and operational learning, it significantly enhances students’ comprehension of modern automotive engineering concepts.

Through its integrated MCU control system, the automotive training equipment can simulate the hybrid power system’s operation under six realistic working conditions: starting, low-speed driving, normal driving, full-speed driving, deceleration, and parking. These simulation modes allow learners to intuitively understand the dynamic behavior and energy flow of the hybrid system during different phases of vehicle operation.

Core Features

1. Comprehensive Range of Automotive Training Equipment

We provide a comprehensive range of automotive training equipment and systems designed for classroom and training center applications. Our solutions incorporate current industry trends and best practices, giving learners both practical knowledge and hands-on experience. These training systems meet modern instructional standards while delivering clear understanding of automotive mechanics, diagnostics, and repair procedures.

2. OEM-Based Hybrid Power System Training

Our Hybrid Transmission and Engine Automotive Training Equipment incorporates an OEM parallel hybrid system complete with engine, generator, and electric motor components. The precisely sectioned and color-coded mechanical systems provide clear visualization of both internal and external structures. This hands-on learning approach enables comprehensive understanding of hybrid powertrain configurations, effectively bridging theoretical knowledge and practical application.

3. Durable, Mobile, and Education-Oriented Design

The training equipment is constructed from high-strength welded steel with an industrial-grade spray coating for enhanced durability. It features a mobile stand equipped with lockable caster wheels, enabling easy repositioning during training sessions. The cutaway design combined with color-coded hybrid components improves visibility and simplifies the explanation of both individual component functions and overall hybrid system operations.

4. Interactive Demonstration of Mechanical Movements

The Hybrid Transmission and Engine Automotive Training Equipment utilizes a gear-reduced induction motor to drive both the engine crankshaft and motor shaft at low speeds across various operating conditions. This dynamic demonstration accurately replicates mechanical movements in a parallel hybrid system, providing learners with a realistic yet safe environment to observe internal component interactions. Our offerings also include comprehensive automotive training systems covering both traditional and hybrid engine operations.

Technical Specifications

Product Name: Hybrid system engine transmission system anatomy display stand

Model: ZC-QCG55

Dimensions: about 1400×800×1000mm (length×width×height)

Gear Reduction Induction Motor:

Rated Voltage: AC 220V 50Hz

Rated Power: 120W

Rated Speed: 50Hz 90/1400rpm

Reduction Ratio: 30

Operating Temperature: -40℃~+50℃