INTRODUCTION: Exploring the Impact of Electric Vehicles on the Automotive Repair Industry

With the increasing expansion of electric vehicles (EVs), the traditional automobile repair business is undergoing significant upheaval. Many people are concerned that the popularity of EVs may leave mechanical repairers out in the cold or possibly cause the entire business to fade away. However, this notion is not correct. They will not put an end to the car repair sector but rather move it in a new direction.

In this article, we will examine the impact of electric vehicles on the automotive repair industry, as well as the new opportunities and challenges they present, and propose ways for various repair companies, vocational training institutes, and repair centers to effectively transform themselves in the new market environment.

1. How the automotive repair industry is evolving as a result of being influenced by new technologies

Every innovation in automotive technology tends to drive change in the industry; if adapted and mastered ahead of the new technology, some maintenance technicians will be able to create new career opportunities, including high-paying positions. Looking back in time, the fuel injection system, for example, gradually replaced the traditional carburetor system beginning in the 1970s. Although many mechanics were initially opposed to this change, the technology not only increased automotive fuel efficiency and environmental performance, but it also drove the maintenance business to a greater degree of technological sophistication.

1.1 The shift in technology needs to be brought about by electric vehicles:

With the rapid growth of electric cars (EVs), global EV sales have increased from around 500,000 units in 2015 to more than 10 million units by 2022, accounting for around 14% of global vehicle sales. The market share of EVs is predicted to exceed 30% by 2030 [source: International Energy Agency (IEA)]. This trend implies that demand for traditional fuel vehicle maintenance will decline, and maintenance personnel with electric vehicle expertise will become increasingly scarce.

Electric vehicles have 20–30% fewer mechanical components than internal combustion engine vehicles, but its basic technology is more dependent on electronics and intelligence. For example, EVs have high-voltage battery systems, electric drive modules, regenerative braking systems, and complicated electronic control units (ECUs), and repairing and diagnosing these components necessitates a greater understanding of electricity and electronics among professionals. According to industry research, more than 70% of technicians believe their existing abilities are insufficient to meet the repair needs of electric vehicles [source: McKinsey & Company].

1.2 The Need for New Skills in Electric Vehicle Maintenance:

EV maintenance necessitates not just knowledge of high-voltage electrical system operation (voltages can reach 400-800V, far above the 12V system of traditional vehicles), but also expertise in software diagnostics and troubleshooting. According to data, the diagnostic and troubleshooting time for EVs is around 30% longer than that of standard internal combustion vehicles, and they rely on highly integrated technology such as battery management systems (BMS) [source: Deloitte Research]. As a result, automobile mechanics must enhance their knowledge through specialist EV training, notably in high-voltage systems, electric drive technology, and regenerative braking.

1.3 Industry transformation and new opportunities:

While the spread of EVs provides new obstacles, it also creates opportunities, particularly for technicians with dual capabilities. The demand for technicians with dual maintenance abilities is expected to increase by more than 30% by 2030, and early adoption of EV training courses and equipment can assist repair centers and vocational training institutes in acquiring a strong foothold in the future market.

This is not just a transformation of technology but an important step in the industry’s evolution towards high precision and green sustainability.

2. Differences in the repair and maintenance of electric vehicles

As electric vehicles (EVs) gain popularity worldwide, the automobile maintenance business faces new technological obstacles. While EVs are mechanically simpler than typical internal combustion engine (ICE) vehicles, they differ significantly in their basic components and maintenance procedures. Below, we will look into some major areas of EV maintenance to better understand the practical needs and opportunities that these variations bring.

2.1 Core components of electric vehicles and their maintenance needs

High Voltage Battery System: The battery pack is the most essential component of an electric vehicle, accounting for 30-50% of the total vehicle cost. Batteries not only store and output high-voltage current (about 400-800V), but they also require a sophisticated battery management system (BMS) that monitors critical parameters like as temperature, voltage, and current in real time. According to research, battery system issues account for around 30% of all EV failures [source: McKinsey Consulting]. Battery maintenance and repair require specialized electrical safety knowledge and equipment, particularly for high-voltage operations.

Electric motors and controllers: Electric vehicles rely on electric motors to create drive power, and unlike the complex mechanical drivetrain of an internal combustion engine, electric motors are nearly vibration-free, quiet, and less abrasive. This reduces the frequency of drive train maintenance in EVs by approximately 30% compared to internal combustion engines [source: Deloitte Research]. However, troubleshooting electric motor controllers necessitates specialist electronic expertise as well as debugging using high-precision diagnostic tools.

Regenerative Braking System: Electric vehicles frequently employ regenerative braking technology to increase range and battery life by collecting braking energy. The regenerative braking system turns braking energy into electrical energy and stores it in the battery, requiring technicians to be skilled in both electronic braking and battery management. Regenerative braking systems are more complex to maintain than typical mechanical braking systems since they require regular inspections of current conversion, brake feedback, and other components.

2.2 Brand new requirements for electric vehicle maintenance skills

Software diagnosis and troubleshooting: the troubleshooting of electric vehicles is highly dependent on the diagnosis of the software system. Modern electric vehicles have dozens of built-in electronic control modules (e.g., battery management system, drive system controller, etc.), and once a fault occurs, it is first necessary to detect it through software diagnostic tools. Data shows that the troubleshooting time for EVs is about 40% longer than that of traditional fuel vehicles [source: The Boston Consulting Group (BCG)]. Therefore, technicians need to know and operate these diagnostic software to quickly identify and solve problems.

Electrical and high-voltage operation safety: Compared to 12V traditional automotive circuits, battery voltages in EVs can be as high as 400V or even higher, which poses a safety risk to technicians’ operations. Repair of high-voltage systems requires technicians to be professionally certified and have strict knowledge of safety precautions. This shift will make EV repair more dependent on specialized technicians who are certified in basic electrician and high voltage operation.

Thermal Management and Battery Protection: Due to the nature of batteries operating at high temperatures, EVs require specialized thermal management systems to ensure efficient battery operation and longevity. The maintenance and repair of thermal management systems for EVs also put new demands on the technician’s operational skills, requiring regular testing of coolant status, system sealing, and temperature control device operation.

2.3 Opportunities arising from emerging market demand

Although the popularization of electric vehicles is advancing rapidly, the global ownership of internal combustion engine vehicles is still large, especially in emerging markets such as Asia and Africa. The coexistence of combustion and electric vehicles will lead to an increase in the demand for technicians with “dual-technology” skills, which is an opportunity for maintenance companies and vocational training institutions. According to the study, by 2035, the world will need about 250,000 “dual-skilled” technicians who are familiar with both traditional automotive maintenance and electric vehicle technology [Source: International Energy Agency (IEA)]. With this trend, the sustainability of the automotive repair industry will depend on upgrading the skills of technicians.

3. Vocational Training Opportunities in the Popularization of Electric Vehicle Technology

As EV technology continues to evolve, the demand for qualified EV repair technicians is exploding across the globe. Data shows that about 40% of automotive technicians worldwide in 2023 say they lack the necessary EV repair skills [source: McKinsey]. Meanwhile, the demand for specialized technicians with skills in electric vehicles and high-voltage electrical systems is expected to grow by more than 50% over the next five years [source: BCG].

3.1 Key areas for vocational training

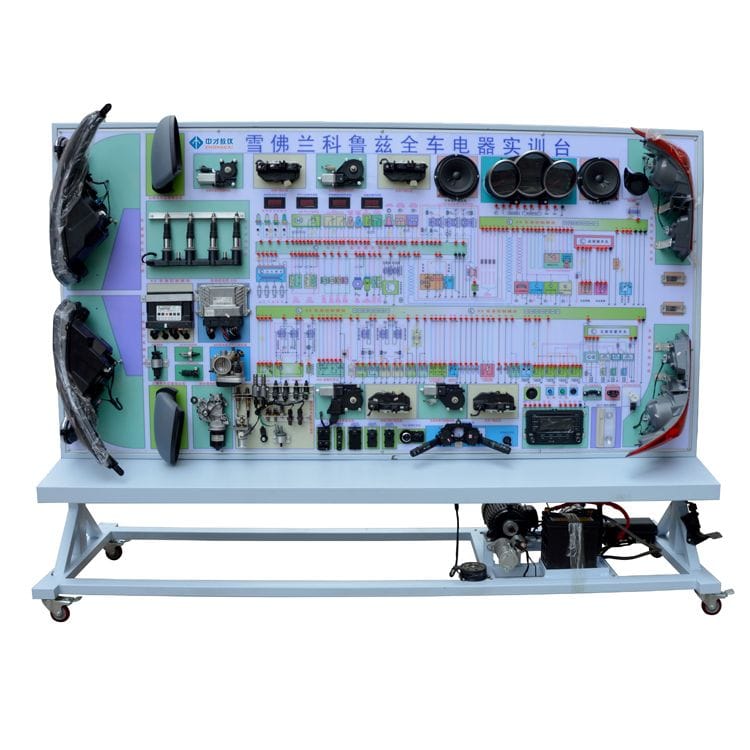

To meet this market demand, vocational training organizations need to offer courses that focus on EV technology, specifically targeting skills in areas such as high-voltage battery maintenance, diagnosis of electronic control systems, and software operation. In response to these high-skill needs, we provide comprehensive training equipment, including high-voltage battery modules, safety operation simulators, and regenerative braking systems, to help technicians gain technical certification and practical experience in real-world operations.

3.2 Support the transformation and upgrading of maintenance enterprises

Providing EV training equipment to maintenance centers and enterprises is not only a guarantee for technical upgrading but also enables them to effectively respond to market changes. By introducing high-quality equipment and training support, enterprises can build teams with dual skills to remain competitive in both the traditional fuel vehicle and EV segments. By continuing to invest in skills upgrades and equipment, the maintenance industry will not be “rendered obsolete”, but will be able to grow sustainably in the new market environment.

4. Future growth and sustainability of the automotive repair industry

With the rise of electric vehicles, the auto repair industry is facing a critical moment of technological transformation. However, this does not mean that the traditional auto repair industry will disappear. On the contrary, the repair industry will enter a phase of diversification and greater specialization as EVs and traditional fuel vehicles coexist. According to the International Energy Agency (IEA), global EV ownership will reach 200 million by 2030, accounting for more than 30% of all vehicles [source: IEA]. This transition will drive the maintenance industry in a more diversified direction.

4.1 Sustainable development of the maintenance industry

With the popularization of EV technology, the traditional automotive maintenance industry will face new challenges, but at the same time, it will also usher in new development opportunities. The retraining of existing maintenance technicians and the introduction of EV-specific equipment will be the key to future development. Such equipment will not only help technicians master EV maintenance skills but also ensure that they can diagnose and solve complex electronic control system problems.

At the same time, maintenance companies will need to continuously upgrade their technology to provide comprehensive services, including battery management, drive systems, and charging facilities. This diversification of technology and services will not only continue the vitality of the traditional maintenance industry but also propel it into higher-value technical services.

4.2 Our support and solutions

As a provider of automotive training equipment, we offer comprehensive technical support and training equipment for the future development of the maintenance industry. Whether it’s battery systems, electric drive modules, or intelligent diagnostic equipment, our products help training institutes and repair centers accelerate their transformation and upgrade their skill levels in response to rapidly changing market demands.

5. Meeting the Opportunities and Challenges of the Electric Vehicle Era

With the rapid development of electric vehicle technology, the automotive maintenance industry is facing a profound change. This not only requires maintenance companies to make rapid adjustments in equipment and technology but also puts new demands on the skills of technicians. However, this transformation does not mean the “end” of the industry but rather provides great opportunities for forward-looking companies.

A deep understanding of EV technology and early investment in training equipment is the way to enable maintenance companies and vocational training institutions to remain competitive in the future wave of electrification.