A Guide to Future Trends and Market Strategies in the Automotive Repair Industry

1.Market overview and industry background

1.1 Present of the automotive repair industry

The rapid growth of the global automotive repair industry in recent years has been driven by increasing car ownership and rising technical complexity of vehicles According to Statista, the global automotive repair services market reached $750 billion in 2022 and is expected to grow to $1.2 trillion by 2027, at a CAGR of 6.4 per cent .There are several important reasons behind this trend- Rising car ownership: Car penetration has risen significantly with rising economic levels, especially in Asia-Pacific and Latin America. For example, China’s car ownership has grown from 80 million in 2010 to over 300 million by 2023, while countries such as India and Brazil are showing similar rapid growth.- Longer vehicle lifespan: According to the International Energy Agency (IEA), the average age of vehicles is on the rise globally, reaching 12.1 years in the US and 11 years in Europe. This is a direct result of the increased need for vehicle maintenance.- Increased technological complexity: As vehicle technology continues to advance, modern cars are no longer just mechanical devices, but more like ‘mobile smart devices’. For example, the increased use of electric vehicles, advanced driver assistance systems (ADAS), in-vehicle networking technology and other applications have made maintenance technology increasingly demanding, and traditional maintenance methods are no longer able to meet demand.

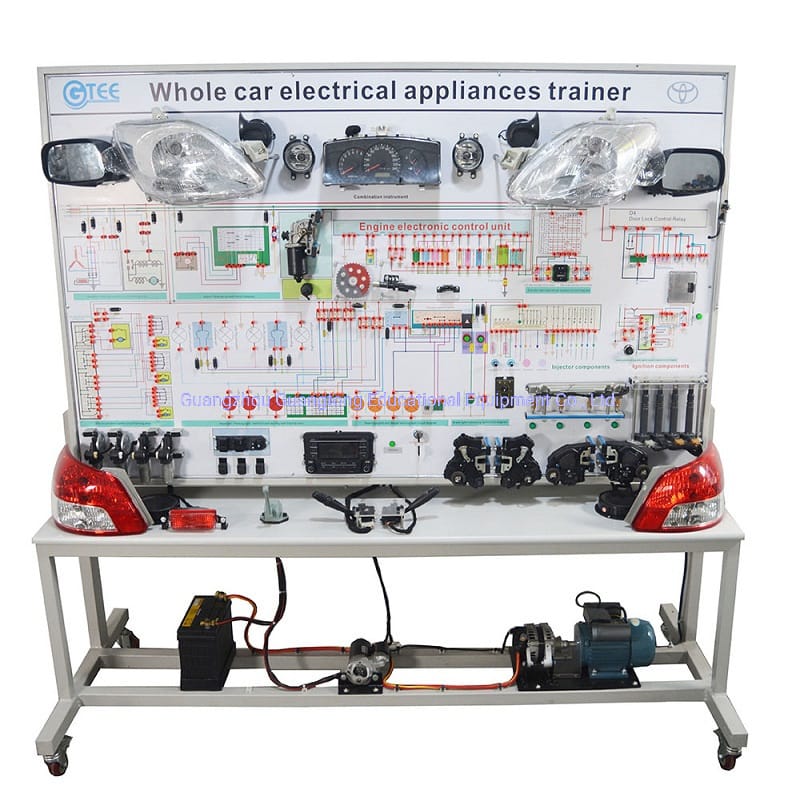

1.2 Importance of automotive training equipment

Against this backdrop, the role of automotive training equipment in the maintenance industry has become increasingly critical Professional maintenance training equipment can effectively help technicians learn and master advanced maintenance skills and meet the challenges of emerging technologies. According to research firm MarketsandMarkets, the global automotive maintenance training equipment market size will grow from USD 9 billion in 2023 to USD 15 billion by 2030, at a CAGR of approximately 7.2%.Specifically, the importance of automotive training equipment is reflected in the following aspects:- Responding to the needs of EV maintenance: EV high-voltage systems, battery management systems (BMS), etc. differ from the maintenance requirements of traditional fuel vehicles. For example, maintenance of EV high-voltage systems requires the use of high-voltage isolation training equipment to ensure technician safety and operational practices.- Technical training related to autonomous driving: The growing popularity of autonomous driving technology has led to increased demand for maintenance of sensors, LIDAR, cameras and other equipment. Advanced automotive training equipment can provide simulations of autonomous driving systems to equip technicians with system calibration and fault detection skills.- Application of Virtual Reality (VR) and Augmented Reality (AR): In order to shorten the learning curve, many training organisations have started introducing VR and AR technology to help technicians operate and repair complex components in a virtual environment. These devices can simulate breakdowns without occupying an actual vehicle, helping technicians to quickly acquire new skills.From the perspective of market demand, automotive maintenance training equipment not only meets the demand for maintenance skills improvement, but also greatly improves training efficiency. Especially those training institutions that cooperate with large maintenance chain brands and car companies, through the introduction of advanced equipment, not only to cultivate high-quality technicians, but also able to shorten the training cycle, and bring higher economic benefits for maintenance enterprises.

2. Industry drivers

2.1 Technological Development

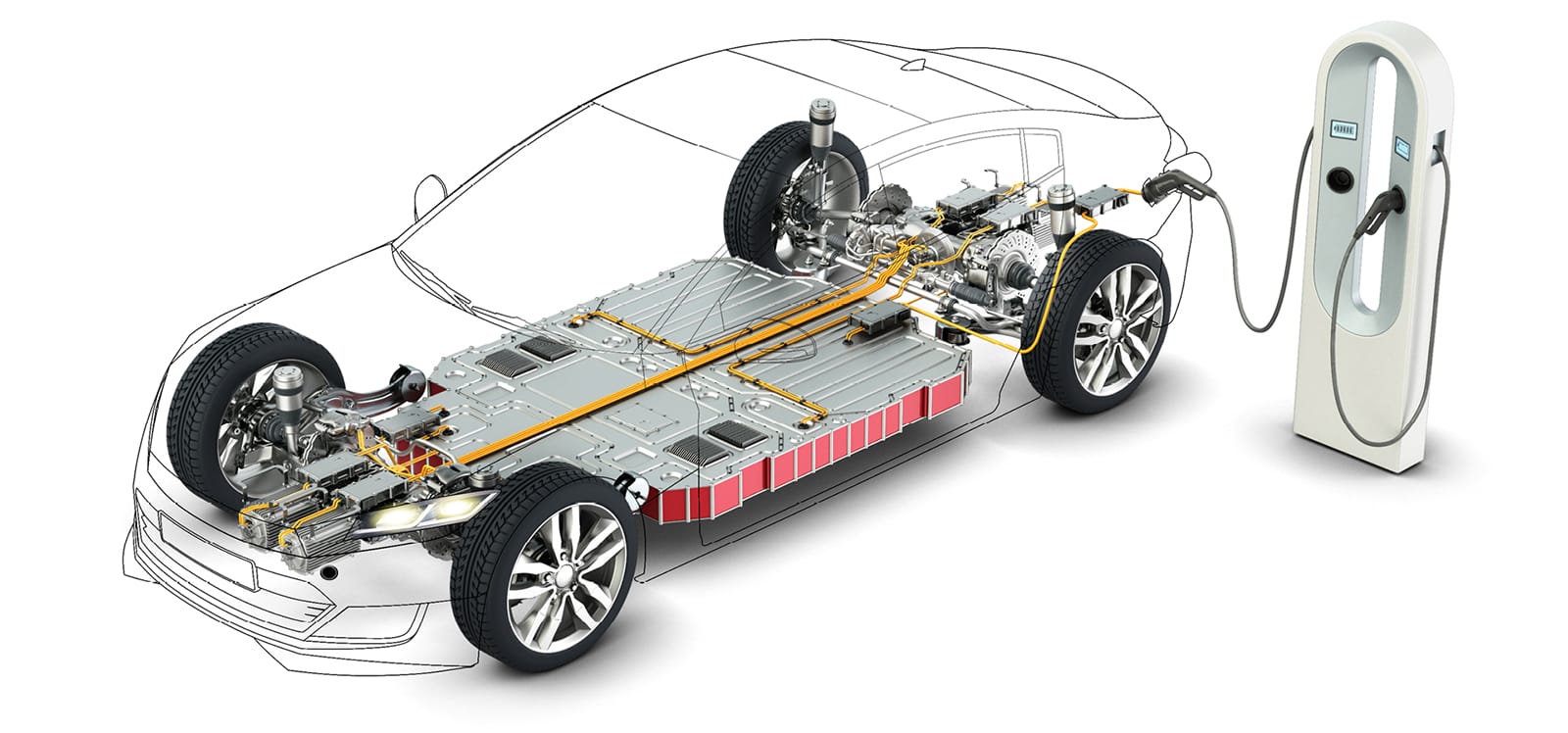

With the rapid advancement of automotive technology, the automotive maintenance industry is witnessing unprecedented changes The proliferation of electric vehicles (EVs), hybrid electric vehicles (HEVs) and autonomous driving technologies has brought new challenges to the maintenance industry, requiring increasingly high levels of skills from technicians Traditional maintenance techniques are no longer sufficient to cope with the complex demands of new vehicles, driving a strong demand for high-quality training equipment.For example, the high-voltage system and battery management system (BMS) of electric vehicles are complex core technologies that require specialised training equipment for simulation and demonstration According to ResearchAndMarkets, the global EV training equipment market is expected to reach USD 5 billion by 2030, growing at a CAGR of around 8.6% This type of equipment helps technicians get up to speed quickly and ensures that they are able to safely service electric vehiclesIn the self-driving world, maintenance needs are more complex . self-driving cars use a variety of technologies such as cameras, radar, LIDAR, and sensors that require regular calibration and maintenance Repairing and commissioning these devices requires technicians to not only be familiar with how each sensor works, but also be able to detect and troubleshoot potential faults in the system. As a result, there is also a rapidly growing demand for specialised self-driving maintenance training equipment to help technicians understand how to maintain these smart systems.

2.2 Policy Support and Regulatory Changes

Policy support and regulatory changes are also one of the important factors driving the growth of the automotive training equipment market. The gradual tightening of environmental regulations and safety standards has placed higher requirements on maintenance technology. For instance, Europe and North America have introduced stringent environmental regulations that require vehicles to comply with carbon emission standards. This means that the vehicle’s emission control system (e.g. catalytic converter, exhaust gas recirculation system, etc.) has to comply with stringent testing and calibration standards when being repaired, prompting a rise in demand for professional training equipment in the maintenance industry.In addition, in terms of safety regulations, regions such as the US National Highway Traffic Safety Administration (NHTSA) and the EU have introduced new standards for the calibration and maintenance of ADAS (Advanced Driver Assistance Systems). These regulations require that maintenance personnel must be professionally trained and use appropriate equipment for calibration to ensure vehicle safety. According to data, the demand for automotive maintenance and training equipment in the European market is expected to grow by nearly 15 % over the next five years, driven mainly by environmental and safety regulations.

2.3 Changes in Consumer Expectations

Consumers’ expectations of automotive service quality are also rising, and they are placing more and more emphasis on the speed, quality and reliability of service. In particular, the popularity of electric vehicles and smart cars has made consumers more reliant on professional and fast repair services. A survey of the global automotive aftermarket to 2023 revealed that around 70% of consumers said they would prioritise repair centres that have modern equipment and high levels of technicians, which is further driving investment in training facilities by repair companies.This change in expectations has had an immediate impact: repair companies have had to upgrade the competence level of their technicians to meet customer demand for efficient and accurate service. The use of modern automotive training equipment allows technicians to master new techniques faster and provide customers with higher quality repair services. This not only improves customer satisfaction, but also enhances the competitiveness and brand reputation of the company.

3. Analysis of major trends

3.1 Electric and Hybrid Vehicle-Related Training Equipment

With the rapid popularisation of new energy vehicles, the demand for maintenance training for electric vehicles and hybrid powertrains has increased significantly. Nowadays, more and more maintenance companies are aware of the importance of training equipment in the maintenance of new vehicles, especially for the training demand for core technologies such as battery management system (BMS), electric drivetrain and high-voltage electrical system.Data shows that the global new energy vehicle market is expected to grow at a compound annual growth rate of more than 20 per cent, and by 2030, sales of electric vehicles will reach more than 50 million units. This trend is fuelling the growing demand for electric and hybrid vehicle maintenance training equipment. Specialised electric vehicle training equipment can help technicians quickly master new energy vehicle maintenance techniques and ensure that they operate in a safe environment, thereby reducing the risk of repairing high-voltage systems.

3.2 Training Needs for Autonomous Driving and Intelligent Technologies

Advances in autonomous driving technology are also changing the direction of automotive maintenance training. With the development of ADAS (Advanced Driver Assistance Systems) and automated driving technology, there is a growing demand for training involving radar, camera, lidar and other intelligent systems. Maintenance technicians not only need to be able to operate them, but also need to understand the calibration, troubleshooting and diagnosis of the systems, which puts a higher demand on training equipment.According to Statista, the global ADAS market is growing at an annual rate of 16.3%, and the continuous advancement of autonomous driving and intelligent systems has made it imperative for maintenance technicians to acquire more specialised maintenance skills. Corresponding automated driving training equipment is also rapidly evolving to help technicians simulate and learn how to maintain these complex sensors and systems to ensure the safety performance of their vehicles.

3.3 Application of Virtual Reality (VR) and Augmented Reality (AR) Technology in Training

The application of Virtual Reality (VR) and Augmented Reality (AR) technologies is becoming a mainstream trend in automotive maintenance training. The addition of these technologies makes training more immersive and interactive, simulating real vehicle environments and breakdown scenarios so that trainees can practice operations safely and improve learning outcomes.According to ResearchAndMarkets, the global VR/AR training market is predicted to reach $25 billion by 2028, with a significant portion of that applied to the automotive maintenance industry. Using VR and AR technology, maintenance personnel can train on operations in a virtual environment without having to actually disassemble the vehicle, saving costs and improving the efficiency of skill acquisition.

3.4 Distance and online training needs

One of the impacts of the epidemic has been the widespread acceptance and application of distance and online training modalities. Remote training equipment and technical support have enabled maintenance personnel to receive professional training regardless of location, which has greatly broadened the coverage of training and reduced the time and cost of training.For example, using live teaching, remote support and other technical means, trainees can interact with instructors through virtual classrooms and even operate virtual equipment in real time. According to industry research, the adoption rate of remote training modes increased by more than 70 per cent after the epidemic and has become an important tool for many maintenance companies to improve training efficiency.

3.5 Development of modular and multifunctional equipment

With the diversification of vehicle types and technologies, maintenance training equipment is also developing in the direction of modularity and multifunctionality Modern maintenance equipment not only needs to be adapted to different types of vehicles, but also needs to cover the maintenance and diagnosis of multiple systems. modular design allows the equipment to be more flexible and adaptable to changing maintenance needs.The advantage of modular equipment is that it can be quickly adapted to different vehicles or systems. According to the research firm, the modular equipment market is expected to grow by more than 15% over the next five years, driven by the demand for multifunctional, easily upgradable equipment in the maintenance market. This multifunctional modular equipment not only reduces the footprint, but also gives maintenance companies the flexibility to respond to diverse training needs, thus saving on investment costs.

4. Competitive landscape and innovation

4.1 Key Market Players

Some of the leading players in the automotive training equipment market stand out due to their innovative technologies and unique advantages. These market players tend to have significant strengths in technology development, market reach and customer support, giving them a leading position in the industry. For instance, companies such as Bosch, Snap-on, and Launch have a long history of developing automotive maintenance equipment and have launched a range of training devices specifically geared towards new energy vehicles and autonomous driving technologies to help maintenance personnel keep pace with industry developments.According to Global Market Insights, these leading companies account for approximately 40% of the global automotive training equipment market. They rely on strong R&D capabilities and global presence to respond quickly to market needs and provide advanced and comprehensive training solutions to their customers. The presence of market leaders also drives other companies in the industry to innovate in order to remain competitive.

4.2 Innovation direction

The innovation direction of automotive maintenance training equipment is mainly reflected in the application of new materials, new technologies and cloud-based data management. Firstly, with the advancement of electric vehicles and self-driving technology, companies have introduced lightweight and durable new materials into training equipment, making the equipment more suitable for mobile and frequent operation. Secondly, the addition of intelligent technology and AI applications has enabled equipment to perform self-diagnostics and automated fault demonstrations, allowing trainees to improve their practical skills in simulated real-life situations.In addition, cloud-based data management is also a major direction of innovation. By cloud-enabling equipment and data management systems, maintenance companies can remotely monitor the operating status of their equipment and update their systems and functions online according to demand. McKinsey’s industry research shows that equipment using cloud-based data management extends its service life by an average of 20 per cent and significantly improves maintenance efficiency. Supported by cloud-based technology, training facilities have access to the latest training content and specifications at all times, ensuring that maintenance personnel can keep abreast of industry trends.

5. Opportunities for future growth

5.1 Growth opportunities in the new energy vehicle maintenance market

With the popularity of new energy vehicles, the demand for the new energy vehicle maintenance market is showing explosive growth. According to market data forecasts, the average annual growth rate of global electric vehicle sales is expected to reach more than 23% in the next five years, which means that the corresponding maintenance market will also expand rapidly. New energy vehicles are significantly different from traditional fuel vehicles in terms of power system and electronic control, which makes professional training equipment an indispensable tool for the maintenance industry.Especially in core areas such as batteries, drive motors and electronic control systems, professional training equipment can not only help technicians efficiently master maintenance skills, but also ensure the safety and accuracy of maintenance work. Therefore, enterprises can seize market opportunities by investing in advanced training equipment for new energy vehicles to meet more customer needs in the future.

5.2 Cross-industry co-operation

Cross-industry co-operation brings new possibilities to the automotive training equipment industry, especially in collaboration with automobile manufacturers, educational institutions and technology development companies, where all parties can share resources and promote the acceleration of technology development. For example, by collaborating with automakers, training equipment companies can access the latest models and technical information to ensure that equipment content keeps pace with market demand; while collaboration with educational institutions can help training equipment companies become more deeply involved in talent development, thereby building brand influence among potential customers.In addition, technology research and development companies can provide training equipment with advanced technologies such as AI and big data analysis to enhance the intelligent level of the equipment and make the training process more interactive and hands-on. Industry research shows that companies with cross-industry co-operation are more than 30% more efficient in technological innovation and market expansion than those with independent R&D, which creates a broader space for development.

5.3 Cultivation and Retention of Technical Talents

With the increased demand for highly skilled technical personnel in the automotive maintenance industry, how to attract and retain excellent technical personnel has become the focus of attention for many enterprises. Efficient and intelligent training equipment can not only help enterprises improve the skill level of their employees, but also attract more excellent technicians in the recruitment process. By using these devices, companies can demonstrate to potential employees that they value technological advancement and employee development in their corporate culture, thus enhancing their attractiveness.At the same time, continuous training within the organisation can also help retain skilled personnel. Data shows that companies with good training programmes reduce staff turnover by around 25%, especially in technically demanding and fast-moving industries, where high-quality training enhances a sense of professional belonging. By providing up-to-date training equipment and learning resources, organisations can continually upgrade the skills of their employees, giving them an edge in a highly competitive talent market.

6 Market Outlook

In summary, the automotive maintenance training equipment industry is ushering in unprecedented development opportunities. With the rapid popularisation of new energy vehicles, the advancement of autonomous driving technology, and the rising demand for highly skilled personnel in the maintenance industry, the market demand for professional training equipment will continue to grow. It is expected that in the next 5-10 years, the global market investment in training equipment will increase significantly, especially in the field of new energy vehicles and autonomous driving equipment demand is more robust. Various data show that the automotive training equipment market is expected to grow at a compound annual growth rate of more than 7% by 2030, providing the industry with solid support for long-term development.In addition, with the continuous evolution of technology, the intelligent and modular trend of training equipment will also drive the technological upgrading of the entire industry. Enterprises that can seize this opportunity to continuously optimise and upgrade their equipment are likely to stand out in future market competition.